Construction Begins

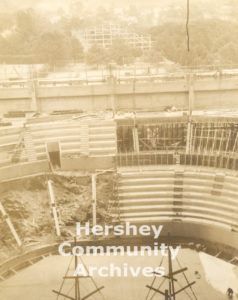

Tedesko realized that the Hershey project would be a unique challenge. He referred to it as a “home-made structure, constructed by Hershey men.” Tedesko became the planner/architect/engineer/construction manager. Milton Hershey wanted to save money and refused to formally hire a construction manager. The result was a rather chaotic beginning. Eventually, Tedesko secured the help of Oscar Spancake, a carpenter-foreman, who mobilized a crew of 250 men, 4 concrete mixers and 2 elevators. The workers had no previous experience in concrete construction, leaving Tedesko no choice but to supervise all aspects of the concrete pours. Remarkably, by July 2, 1936 pouring for the first roof section began.

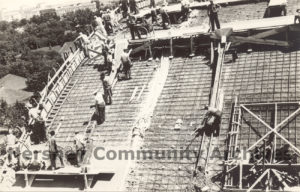

Formwork for the sections was made up of a patchwork of standard lumber sizes, since Milton Hershey had stipulated that all the lumber associated with the project later be used in the construction of barns and homes in Hershey. The scaffolding structure was composed of over 300,000 board feet of yellow pine lumber and the entire scaffolding and formwork structure was placed on a series of 250 jacks. The pours were simultaneously started on both sides from the ground level, and didn’t stop until the two sides came together at the top of the arena. These pours took anywhere from 14 to 20 days, working 24 hours a day.

George Booth had vivid memories of the construction:

Yes, I remember when that was going up. And that windowless office building, too. But that arena job was unbelievable, the number of men. How it was a continuous concrete pour with that kind of equipment, you had to push a truck, probably 800, 900 pounds of concrete in it, wet concrete, push it up ramps, somebody helping to pull you, pouring 24 hours right around the clock.

After a minimal time of curing, the plan was to lower the support jacks and the forms would drop away from the concrete shell. The first time this step was taken, D. Paul Witmer feared that the structure was about to collapse. As they lowered the support jacks the concrete continued to stay attached to the forms for the first 2 inches. Much to his relief, the concrete shell stopped settling and separated from the scaffolding as the forms were lowered further.

As the work progressed, the workers gained skill and subsequent sections were completed more efficiently. Pours were still being made when the temperature dropped significantly. If the concrete froze the structure would be ruined:

Again from George Booth:

It got cold, and Paul [Witmer] made a deal with the city of Philadelphia to have carloads, rail cars, brought up here with manure to cover that concrete, to help it cure, you know. Today you couldn’t do a thing like that. As a matter of fact, it would take longer to get a permit to build a building like that than it took to build it under today’s regulations.

When it opened on December 19, 1936, the Hershey Arena was the first large scale barrel shell roof structure in the United States. Its construction established Anton Tedesko as the preeminent engineer for such structures.